Impregnation

Resin impregnation is one of the techniques used in various applications in the electrical and mechanical industries. It is mainly used to ensure that the liquid resin completely fills the tiny spaces in a solid or an object prior to curing. This technique is immensely useful in providing lasting, insulative and cohesive characteristics, thus suitable for devices such as transformers, motors and coils which do not only require heat and voltage protection but cover environmental conditions as well.

Resin Impregnation in Electrical Applications

As epoxy resin has numerous properties and advantages, it has been widely used for transformer insulation. This is because it can cut down the size and weight of a transformer by at least 50%, bears temperatures as high as 180 degrees Celsius, and has high insulation properties. Therefore, it forms a strong and flexible part capable of enduring extreme operating conditions. Quality epoxy types of resin have high volume resistivity and can sustain working voltage levels of 20, 000 volts before any breakdown. The manufacturers of resins are fundamental in making sure that the electrical insulating properties of the manufactured resins are very high.

The Impregnation Process and Technical Requirements

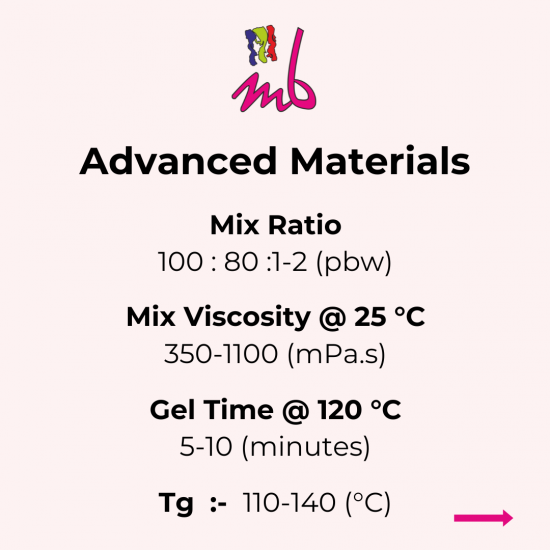

A well executed resin impregnation process eliminates air pockets within the component windings. It is necessary to do this in order to avoid the occurrence of discharges which could result in insulation rot. Epoxy resin systems with a low working viscosity, sufficient pot life and a low vapour pressure are considered appropriate as they easily infiltrate into small voids allowing for effective resin filling prior to curing. In addition to this, the resin should be able to relieve thermal and cracking stresses in order for it to function effectively. Epoxy urea formaldehyde, which is mainly used in the oil-filled transformers, is widely used because of its moisture resistance and durability.

Epoxy Encapsulation as a Complementary Process

Even though resin impregnation reinforces the internal structure of the component, epoxy encapsulation provides firm external protection. In some cases, both procedures are applied simultaneously. Initially, an encapsulation layer is formed around the element, resulting in a rigid shell. Then, a thin resin used for impregnation is injected to occupy the internal space which enhances insulation and provides stability to the construction. This combined method is beneficial in harsh conditions as it protects from moisture, corrosion and mechanical damage.

Applications of Resin Impregnation in Industry

The resin impregnation plants are frequently utilised in industries dealing with heavy electrical components like motors and generators for the purpose of LT/HT motor stator and rotor coils in resin/varnish. This process helps in improving insulation resistance, increasing efficiency and serving in high voltage environments for a longer period of time. Today, resin impregnation is believed to be an essential process so that the appliances can withstand wear regardless of the harsh conditions they are operating in.

Using resin impregnation and epoxy encapsulation are highly advanced procedures in industrial applications. While impregnation supports the inner filling of a component, epoxy encapsulation serves as the outer layer which protects the component; in turn, these two processes increase the durability of transformers, motors and other devices. For better quality and reliable solutions, MB Enterprises - one of the top epoxy resin manufacturers in India offers quality engineering resins which are designed specifically for the demanding purposes of this nature, providing optimal performance as well as durability of the components.

-2462x2317.png)

-550x550.png)