Electrical Material

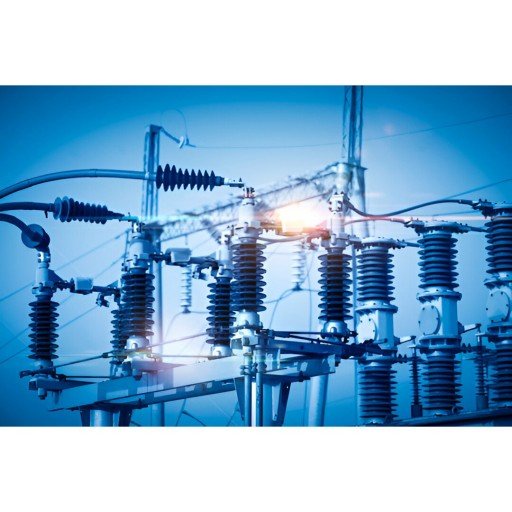

As the electrical world continues to develop, cast resin transformers are emerging as a popular type of alternative to oil-filled transformers. Their robust construction, insulation properties, and ability to withstand hostile environments make them a suitable transformation device for high performance and long periods of use in industrial applications.

With the introduction of resin cast current transformer technology, you can count on reliable performance, minimal maintenance, and improved safety in power distribution, industrial automation, and renewable energy systems. By using the right resin cast transformer materials, businesses can boost their operational efficiency while keeping long-term maintenance costs down.

The Role of Casting in Transformer Manufacturing

The process of casting is most critical for epoxy resin manufacturers. It involves pouring the resin into an existing mold, often a thin metal or plastic casing, to envelop the electrical part. For the resin to effectively fill every nook and cranny around the part, it needs to be in a liquid state. This ensures that no air pockets are left behind. There are several key advantages to this process:

Complete Encapsulation & Moisture Protection:

The casting process makes sure that every part of the transformer gets a good coating of resin, which helps shield the components from water, dirt, and other unwanted stuff. This is particularly important for transformers installed in difficult conditions, where water intrusion would then result in electrical failure.

Enhanced Mechanical Strength & Durability:

Resin cast transformers are shock-, vibration-, and mechanical stress-resistant, making them ideal for heavy industry. Rigid nature does not permit displacement of the components, and therefore there is extended life without considerable wear and tear.

Rigidity & Shock Resistance for Longevity:

A well-crafted resin strikes the perfect balance between rigidity and shock absorption, which is crucial for ensuring electrical stability in transformers. It ensures that voltage remains steady and performance stays consistent.

Reduction in Weight & Voltage Breakdown Risks:

Compared to oil-filled transformers, a cast resin type of transformer is lighter in weight but possesses high dielectric strength. This reduces the likelihood of voltage breakdown and maximizes overall safety in electrical equipment.

Why Choose Resin Cast Transformers?

Resin-cast transformers offer quite a few perks compared to their traditional counterparts. This explains why many industries that need top-quality electrical gear often go for resin-cast transformers. Here are some of the main benefits they bring to the table:

High-Voltage Applications for Exceptional Electrical Insulation:

The epoxy resin within the transformers provides enhanced insulation. It contributes to the prevention of electrical arcing and shorts. This characteristic is important in cases of high voltage applications as reliability is critical.

Superior Thermal Stability for Consistent Performance:

Managing heat is a big deal when it comes to transformers. A resin-cast transformer is designed to withstand intense thermal loads without breaking down. Thanks to the high thermal conductivity of resin, it efficiently spreads out heat, which helps prevent overheating and ensures solid thermal performance.

Minimal Maintenance & Longer Operational Life:

Compared to oil-filled transformers, which require regular oil tests and replenishments, resin cast transformers are nearly maintenance-free. Liquid insulation does not exist to leak, spill, or become contaminated, and they are a cost-effective long-term solution.

Resistant to Environmental Extremes:

You can find resin-encapsulated current transformers in all sorts of places, like bustling factories and humid coastal areas. These transformers are designed to handle a variety of tough conditions, thanks to their outstanding insulation properties and ability to resist dust.

The Importance of High-Quality Cast Resins in the Electrical Industry

High-performance resins play a vital role in the manufacture of electrical equipment excluding transformers. Cast resins find wide applications in motors, generators, switchgear, bushings, and insulators and are marked by high dielectric strength and mechanical stability.

In electronics, epoxy resins, one of the most commonly utilized cast resins, are indispensable in:

1. Encapsulating Integrated Circuits & Transistors

Epoxy resins are extensively used for overmolding delicate electronic components like transistors and hybrid circuits, protecting them from electrical interference and mechanical damage.

2. Manufacturing Printed Circuit Boards (PCBs)

The structural integrity of PCBs is enhanced by using high-grade epoxy resins, which provide heat resistance, electrical insulation, and mechanical strength.

3. Ensuring High Dielectric Strength for Electrical Safety

The dielectric properties of resin-cast transformers are crucial in preventing short circuits, maintaining electrical stability, and improving the overall system reliability.

Through collaborations with industry giants in India for manufacturing epoxy resins, transformer firms are guaranteed to utilize superior-grade materials with high industrial standards.

Choose MB Enterprises for Premium Resin Solutions

At MB Enterprises, we are experts in providing top-grade resin formulations that are specifically tailored for cast resin type transformers and other industrial electrical applications. Being among the top epoxy resin manufacturers in India, we have a range of products to provide insulation, mechanical strength, and durability.

If your business needs high-performance transformers that need resin materials of the highest quality, then MB Enterprises is your best resource. Contact us today for resin solutions to meet your manufacturing needs along with industry quality standards.

-2462x2317.png)